ROOF TRUSS |

A truss is an assembly of beams or other elements that creates a rigid structure. In engineering, a truss is a structure that consists of two-force members only, where the members are organized so that the assemblage as a whole behaves as a single object. A two-force member is a structural component where force is applied to only two points. Although this rigorous definition allows the members to have any shape connected in any stable configuration, trusses typically comprise five or more triangular units constructed with straight members whose ends are connected at joints referred to as nodes.

A roof truss is a structural framework of designed to bridge the space above a room and to provide support for a roof. Trusses usually occur at regular intervals, linked by longitudinal members such as purlins. |

TYPES OF ROOF TRUSSESIn today’s society, more and more focus is placed on safety, and this is why you need to have the best possible roof truss types installed in your home. It’s important to note that the external forces that appear here and their reactions are acting only in the node area, but the way the structure is built allows the dispersion of these forces.

Also, the joints in a truss are seen as revolute, which means that the torsional forces are excluded. But since there are different types of roof trusses, here are the most popular trusses and each of the distinct features they have. |

KING POST TRUSSA king post extends vertically from a crossbeam (the tie beam) to the apex of a triangular truss. The king post, itself in tension, connects the apex of the truss with its base, holding up the tie beam (also in tension) at the base of the truss. The post can be replaced with an iron rod called a king rod (or king bolt) and thus a king rod truss. The king post truss is also called a "Latin truss". Post Truss spans up to 8m, which makes it perfect for multiple types of houses, especially the smaller ones.

|

|

These trusses can be used for spans that range between 6-10m.

|

PRATT TRUSSThe interior diagonals are under tension under balanced loading and vertical elements under compression. If pure tension elements are used in the diagonals (such as eyebars) then crossing elements may be needed near the center to accept concentrated live loads as they traverse the span. It can be subdivided, creating Y- and K-shaped patterns. The Pratt truss was invented in 1844 by Thomas and Caleb Pratt. A Pratt truss includes vertical members and diagonals that slope down towards the center, the opposite of the howe truss.

|

QUEEN POST TRUSSA queen post is a tension member in a truss that can span longer openings than a king post truss. A king post uses one central supporting post, whereas the queen post truss uses two. The said two uprights are placed about one-third of the way from each end of the truss. They are connected across the top by a beam and use a diagonal brace between the outer edges. The central square between the two verticals is either unbraced (on shorter spans), or has one or two diagonal braces for rigidity. A single diagonal reaches between opposite corners; two diagonal braces may either reach from the bottom of each upright post to the center of the upper beam, or form a corner-to-corner "X" inside the square. It offers a good span at around 10m.

|

HOWE TRUSSHowe truss is introduced by an American architect William Howe. It utilizes similar design as Pratt truss, but with a strong difference. Here the diagonal structural beams slope toward the bridge center, while Pratt truss utilizes diagonal beams that slope outward from the center of the bridge. This approach makes diagonal members of Howe truss bridge in compression, while vertical web members are in tension. Howe Truss has a very wide span, as it can cover anything from 6-30m.

|

FINK TRUSS AND FAN TRUSSThe Fink truss in its most basic form has web members that follow a V-pattern which can be repeated several times. As the top chords are sloping downward from the center, the V pattern becomes noticeably smaller. As Fink trusses rely more on diagonal members, they can be very efficient at transmitting loads to the support. Derivatives of the Fink truss include the Double Fink and the Fan truss types. Double Fink trusses are essentially Fink trusses that repeat the pattern twice on either side. If the most basic Fink truss can be characterized by a double-V, then a double fink would look like a double-W. Fan trusses are essentially Fink trusses that have its web members ‘fan out’ from the joints at the bottom, usually the addition of vertical members. This holds around 10-15 meters, which is more than enough for most projects.

|

NORTH LIGHT ROOF TRUSSIt can be used for spans from 20-30m. Commonly used for industrial buildings.

|

When the floor span exceeds 15m, it is generally more economical to change from a simple truss arrangement to one employing wide span lattice girders which support trusses at right angles. In order to light up the space satisfactorily, roof lighting has to replace or supplement, side lighting provision must also be made for ventilation form the roof. It is one of the oldest and economical methods of covering large areas is the North Light and Lattice girder. This roof consists of a series of trusses fixed to girders. The short vertical side of the truss is glazed so that when the roof is used in the Northern Hemisphere, the glazed portion faces north for the best light.

|

QUADRANGULAR ROOF TRUSSQuadrangular truss is a of truss having parallel chords and an arrangement of web members of tension diagonals and compression verticals. It is mostly encountered in auditoriums or railway sheds. This truss may be considered as two trussed rafters, held in place by the tie T at the centre. A famous building with this design is the Madison Square Garden, the biggest arena in New York.

|

PARALLEL CHORD ROOF TRUSSCommonly used in cathedral ceilings, the cost of this truss is higher because it requires the use of steel members to serve as bracing. Many consider the simple lines of the parallel chord roof truss both functional and appealing to the eye. Constructed with two chords running parallel to each other and supported by reinforcing trusses in between the top and bottom chords. This roof truss reduces the condensation problems and mold conditions since they create a vapor barrier.

|

RAISED HEEL ROOF TRUSSRaised-heel trusses are engineered wood trusses fitted with a heel where the bottom chord intersects with the perimeter wall plate which raises the top chord. This additional space allows you to increase the amount of insulation you can use without compressing it, thus reduces the condensation problems and mold conditions since they create a vapor barrier.

|

SCISSOR ROOF TRUSSA scissors truss is a kind of truss used primarily in buildings, in which the bottom chord members cross each other, connecting to the angled top chords at a point intermediate on the top chords' length, creating an appearance similar to an opened pair of scissors. Scissors trusses are used almost entirely in building construction to support a pitched roof, where a sloping or raised ceiling surface is desired.

|

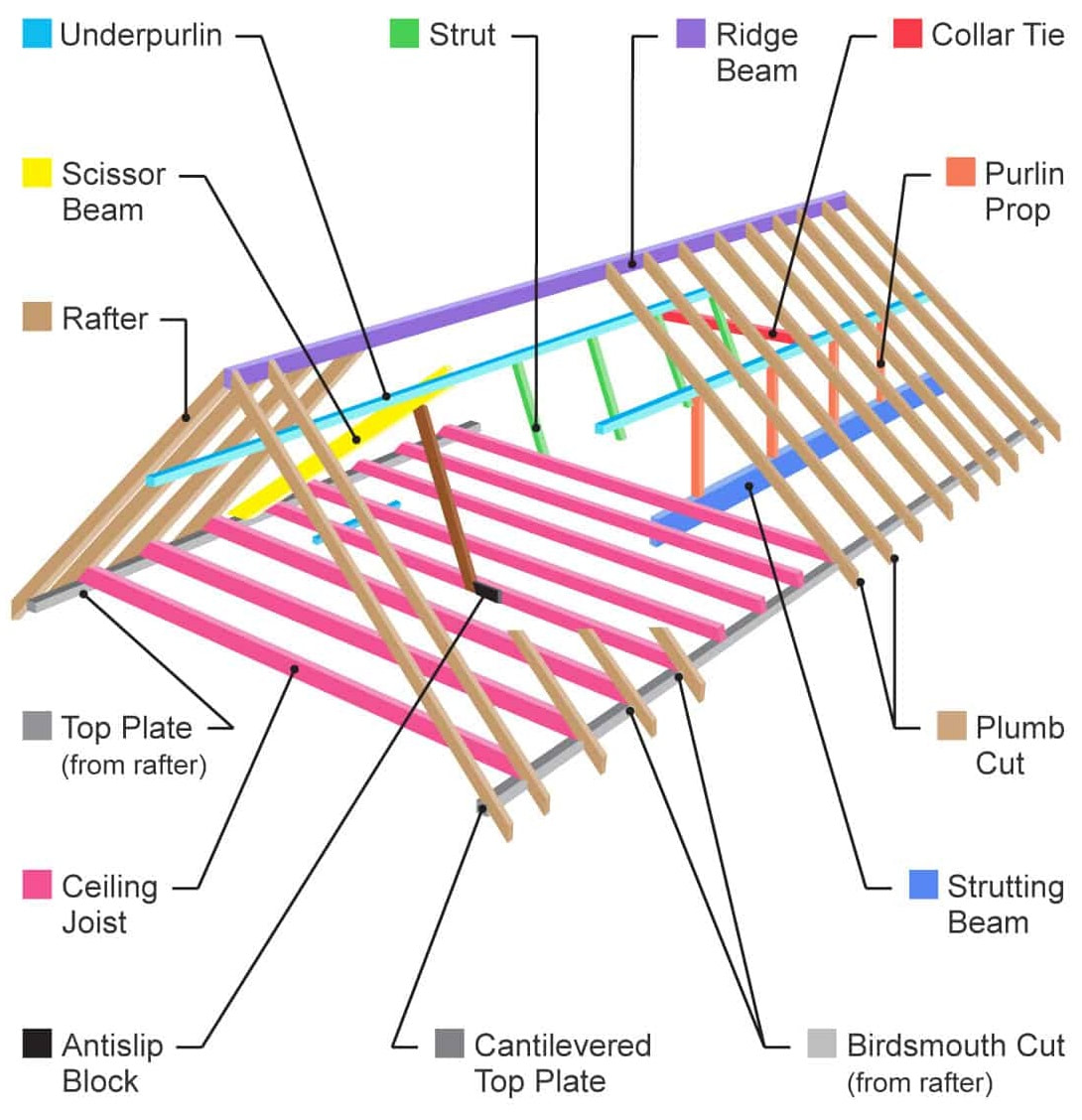

PARTS OF A ROOF TRUSS

Rafter: One of a series of diagonal members of the truss that meet at the apex in order to support the roof deck and its loads.

Underpurlin: Horizontal beams supported by posts and used to support the mid-span of rafters to cover longer spans. These are used in large buildings like the traditional large old barns in the US.

Strut: A diagonal member of the truss that has a compressive force acting on it and used to maintain rigidity and add strength to the structure.

Ridge Beam: So-called because it is the horizontal beam that supports the ends of the rafters at the ridge.

Collar Tie: A horizontal beam that connects two rafters near the ridge of a roof. It is often used to prevent separation of the rafters during high winds but can also be used simply to frame the ceiling.

Plumb Cut: The outward-facing vertical cut of a rafter designed to ram against the ridge board.

Strutting Beam: The horizontal beam that supports roof loads and transfers them directly to load-bearing walls.

Birdsmouth Cut: Also birds mouth joint or bird’s beak cut, it’s so-called because the joint’s indention cut resembles that of a bird’s mouth. It is used to connect the rafter to the supporting wall.

Cantilevered Top Plate: A projecting beam that transports the load it is carrying to a load-bearing support.

Ceiling Joist: The horizontal base that supports the rafters.

Top Plate: The horizontal beam that supports the roof by supporting the rafters to the wall studs.

Underpurlin: Horizontal beams supported by posts and used to support the mid-span of rafters to cover longer spans. These are used in large buildings like the traditional large old barns in the US.

Strut: A diagonal member of the truss that has a compressive force acting on it and used to maintain rigidity and add strength to the structure.

Ridge Beam: So-called because it is the horizontal beam that supports the ends of the rafters at the ridge.

Collar Tie: A horizontal beam that connects two rafters near the ridge of a roof. It is often used to prevent separation of the rafters during high winds but can also be used simply to frame the ceiling.

Plumb Cut: The outward-facing vertical cut of a rafter designed to ram against the ridge board.

Strutting Beam: The horizontal beam that supports roof loads and transfers them directly to load-bearing walls.

Birdsmouth Cut: Also birds mouth joint or bird’s beak cut, it’s so-called because the joint’s indention cut resembles that of a bird’s mouth. It is used to connect the rafter to the supporting wall.

Cantilevered Top Plate: A projecting beam that transports the load it is carrying to a load-bearing support.

Ceiling Joist: The horizontal base that supports the rafters.

Top Plate: The horizontal beam that supports the roof by supporting the rafters to the wall studs.